hopit helps manufacturing companies increase efficiency with real-time data.

Efficiency

Reduce downtime and increase productivity.

Through increased efficiency.

With KPIs based on real-time data.

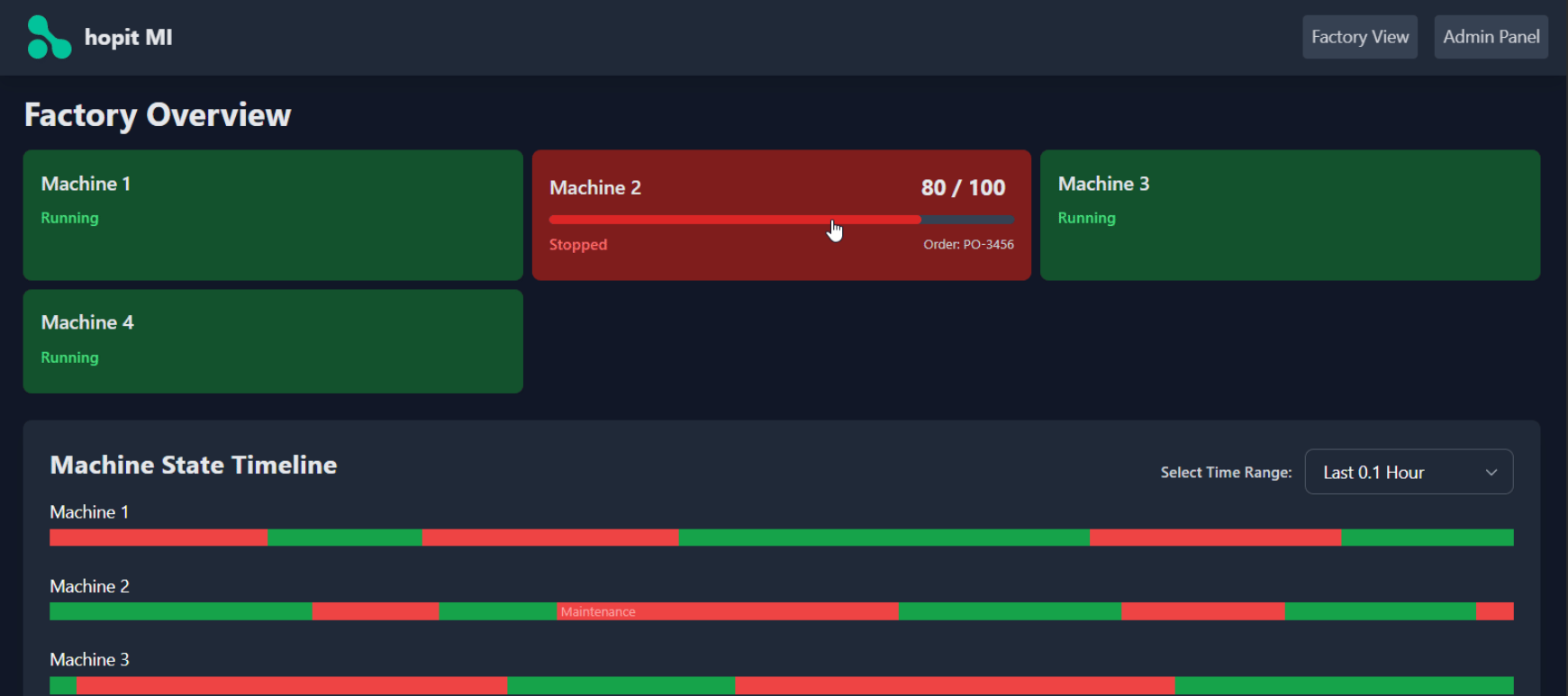

The factory overview shows all machine states including associated order information. This gives you a transparent overview of the entire plant and current production progress – for fast decisions and maximum efficiency.

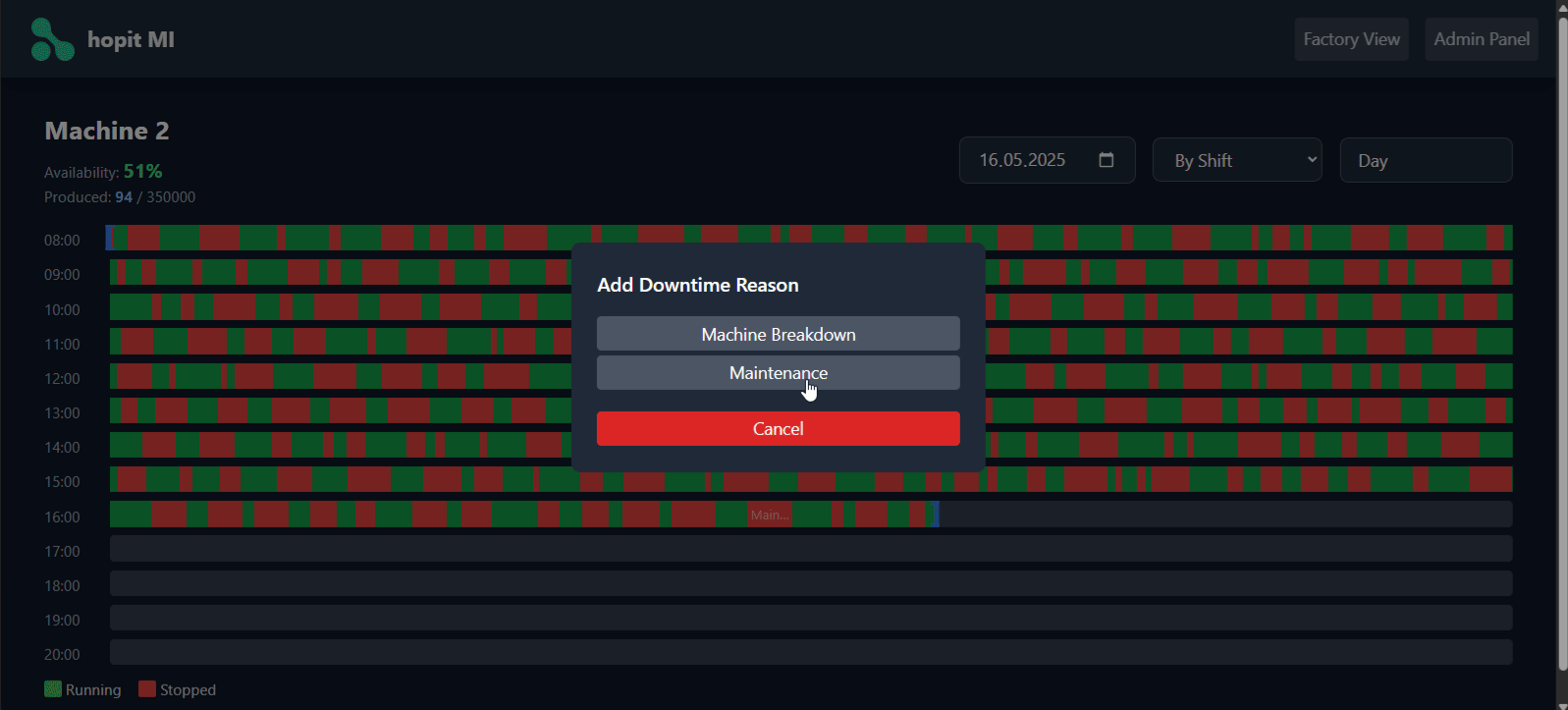

With digital downtime tracking, you immediately detect production interruptions, analyze causes and reduce unplanned downtime. This increases equipment availability and sustainably reduces costs.

Key figures for quality, performance and availability at a glance.

Measurement of required power to reduce energy consumption.

Alarms and notifications in real time for faulty machine states.

hopit Edge

hopit Edge

hopit Edge is our powerful gateway software for machine data connectivity. It connects production (OT) and IT, collects and processes machine data in real time and enables integration of the data into hopit Manufacturing, cloud, MES or local systems.

Within two weeks you will see machine data in real time and benefit from transparency.

1

We analyze your infrastructure and production processes on site.

2

Integration of the hopit gateway and industrial I/O components (e.g. Beckhoff).

3

Capture, structure and visualize machine data in real time.

Optimize your production based on data-driven insights.