Introduction to Equipment Downtime Tracking

In the high-stakes world of manufacturing and industrial operations, every minute of unexpected equipment downtime translates directly into lost production, revenue, and increased costs. To combat this critical challenge, organizations are increasingly turning to specialized Equipment and Machine Downtime Tracking Software. This digital solution is no longer a luxury—it is a foundational tool for maximizing Overall Equipment Effectiveness (OEE) and shifting from a costly reactive maintenance approach to a proactive, data-driven strategy.

What is a Equipment Downtime Tracking Software?

Machine downtime tracking software is a digital system designed to continuously capture, record, analyze, and visualize every instance of equipment non-operational time. It systematically monitors machine activity, logs failures, and provides the context necessary to understand why and when interruptions occur.

Traditionally, downtime was manually logged with limited detail, often leading to inaccurate records and missed opportunities for improvement. Modern software, often integrating directly with the Internet of Things (IoT) sensors and industrial control systems like PLCs (Programmable Logic Controllers) or SCADA (Supervisory Control and Data Acquisition), automates data collection. This crucial automation eliminates human error, ensures data consistency, and provides real-time, accurate visibility into asset performance across the entire production floor.

Key Features of a Downtime Tracking Software

Real‑Time Machine Data Collection

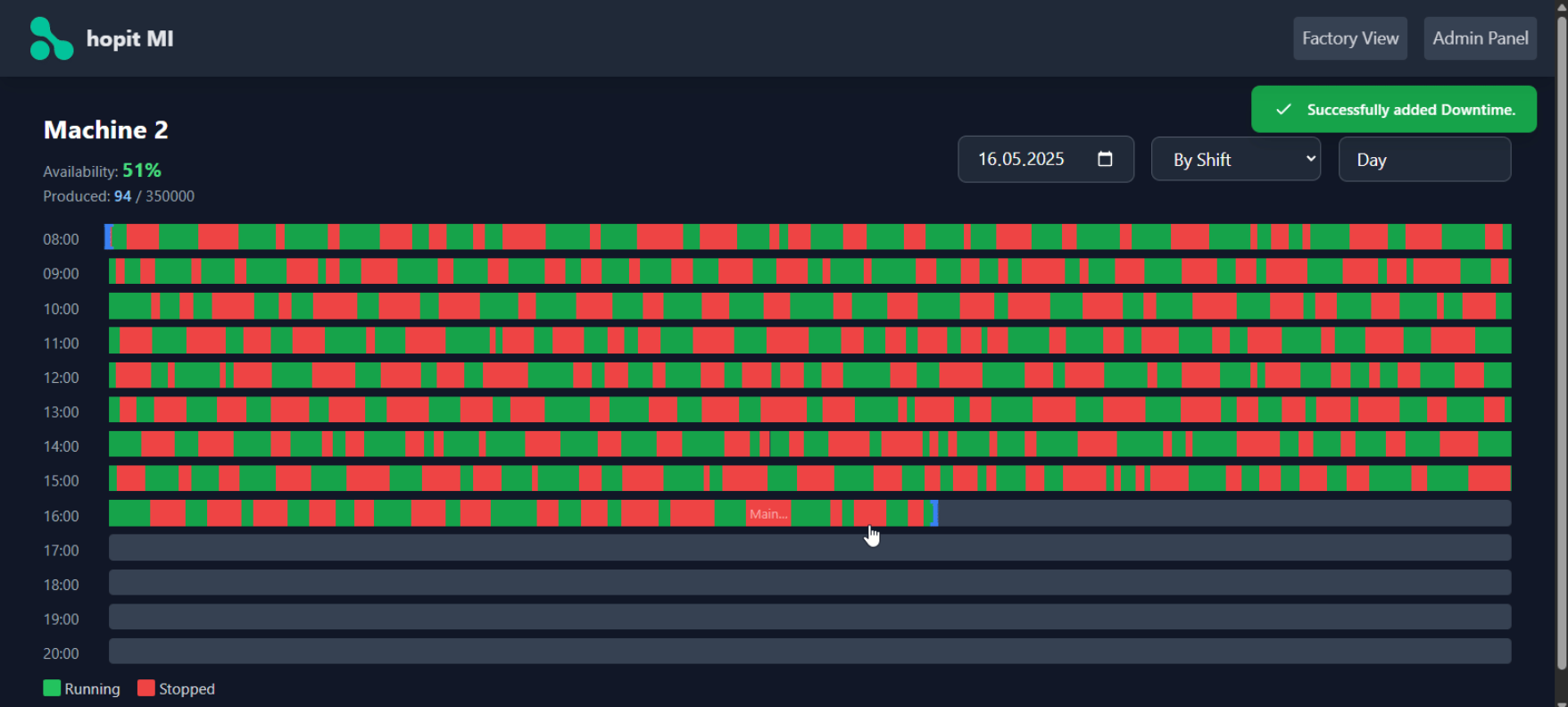

Automated monitoring systems directly connect to the equipment and IoT sensors, detecting every machine state change (Run → Stop) the instant it occurs. This eliminates manual logs entirely.

- ➔ 100% Accuracy: Timestamps are recorded by the machine, not a person, ensuring indisputable data integrity.

Rapid Root Cause Classification

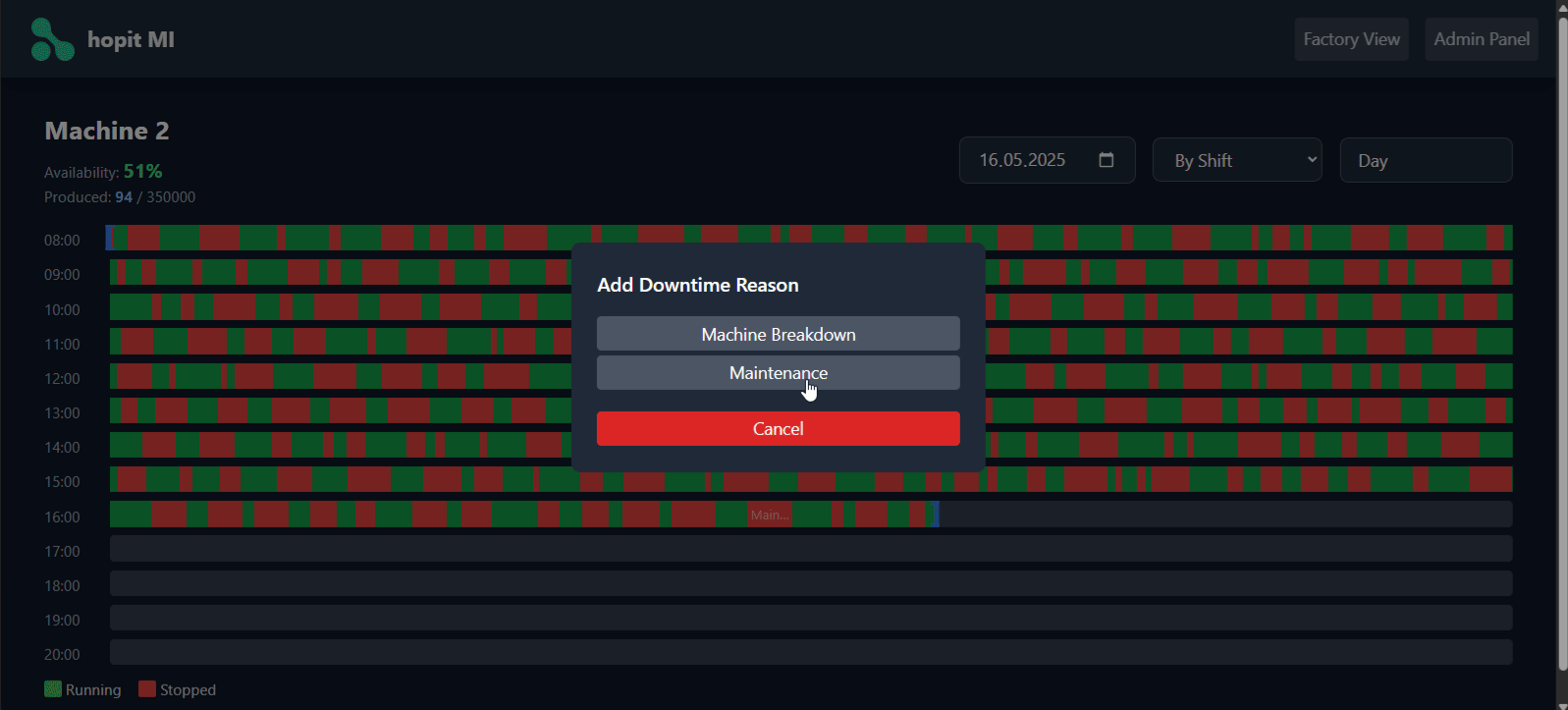

When a machine stops, operators are instantly prompted on a rugged tablet to input the reason via a simple, tap-based interface, capturing crucial context in seconds.

- ➔ Customizable Reason Tree: Structure your reasons according to your internal taxonomy for consistent, standardized data.

- ➔ Low Friction: Designed for speed, ensuring operator compliance remains high.

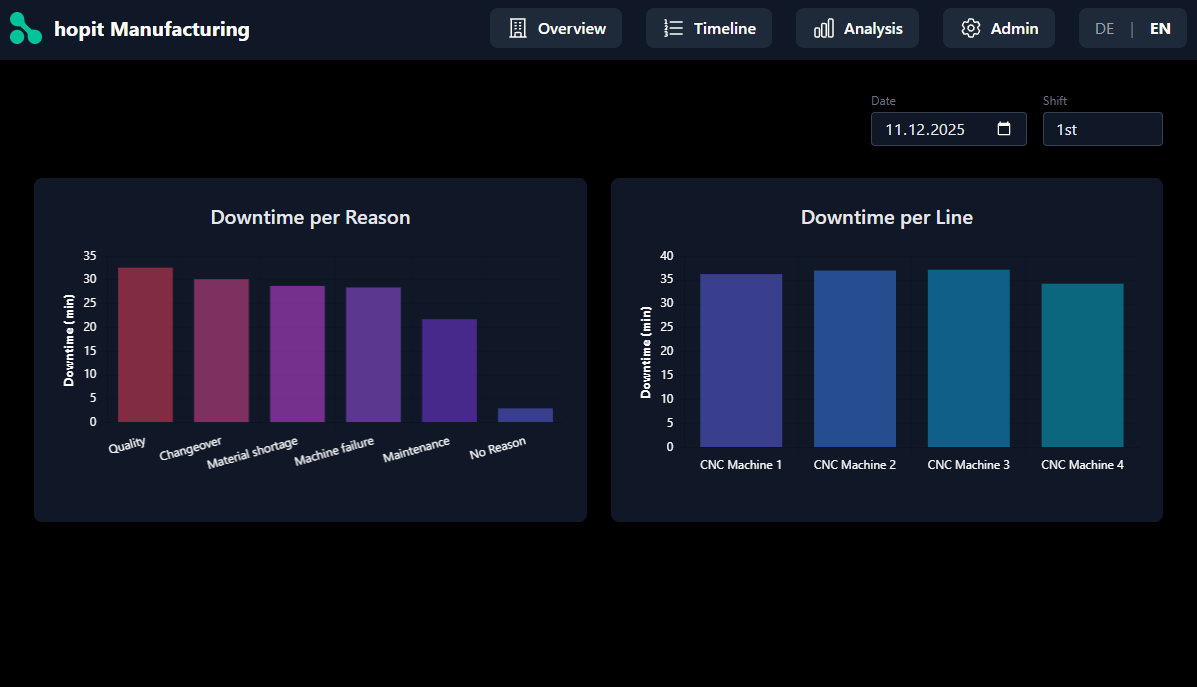

Actionable Analytics and Reporting

Turn raw machine events into prioritized, actionable business intelligence. Comprehensive dashboards empower managers and engineers to focus on the biggest opportunities for improvement.

- ➔ Pareto Analysis: Automatically identify the most impactful reasons for lost time (your "Top 3 losses").

- ➔ Shift Summaries: Instantly evaluate shift performance and benchmark efficiency across teams and equipment.

Ready to Start Tracking?

Try our free Online-Demo showcasing automatic downtime tracking.

TRY OUR FREE DEMOHow it works

A simple, reliable workflow that combines machine event detection with fast operator input on tablets or panel PCs.

Automatic detection

Connect via PLC, OPC UA, ADS, MQTT with hopit Edge to detect stops the moment they happen.

Tablet-first web app

When a stop occurs the operator tablet prompts for a reason — pick from codes.

Dashboards & reports

Real-time dashboards, shift summaries and historical analytics to prioritize fixes and improvements.

Minimize Equipment Downtime: Key Benefits

Downtime tracking software is the foundation for data-driven maintenance and continuous improvement initiatives in any modern factory.