The biggest losses in manufacturing.

There are six main causes of inefficiency in manufacturing. These losses are crucial for identifying improvement potential and increasing productivity.

Breakdowns

Losses due to equipment failures, such as tool breakage or machine damage, leading to unplanned downtime.

Setup Times

Time lost due to setup, changeover or adjustment operations.

Microstops

Small, frequent pauses that typically last less than five minutes and do not require maintenance.

Reduced Speed

When a machine runs at a lower speed than its maximum possible or target speed.

Scrap & Rework

Losses due to defective products that need to be reworked or disposed of.

Startup Losses

Production losses that occur when starting up a machine or at the beginning of a shift.

Overall Equipment Effectiveness

Overall Equipment Effectiveness, or OEE, is a key metric for measuring productivity. It quantifies losses throughout production time.

- Planned Downtime – Breaks, maintenance or planned downtime.

- Availability Loss – Unplanned downtime or setup times.

- Performance Loss – Reduced speed or short stops.

- Quality Loss – Scrap or rework.

hopit Manufacturing at a glance

The OEE software for small and medium-sized companies in the metal and plastics industry. Simple, modern and ready to use.

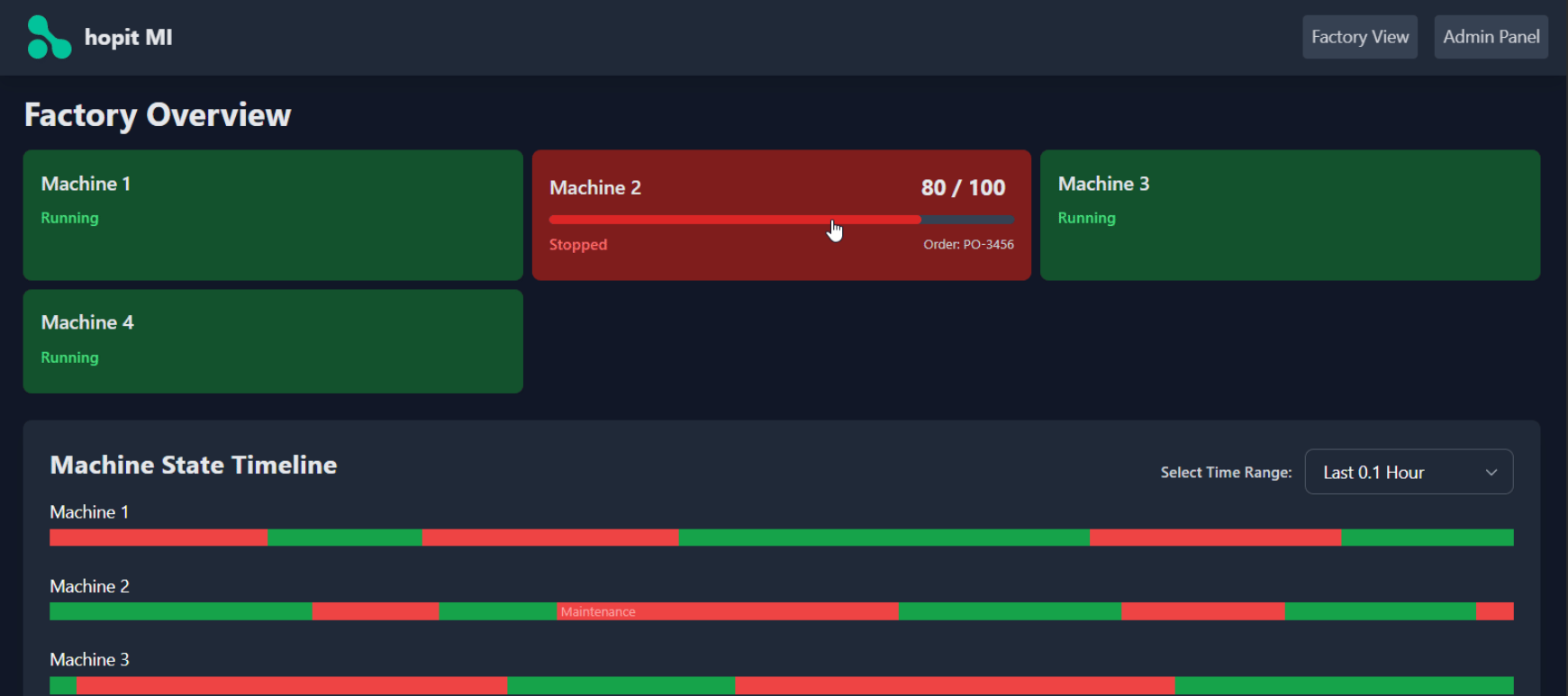

Factory Overview

The factory overview shows all machine states including associated order information. This gives you a transparent overview of the entire plant and current production progress – for fast decisions and maximum efficiency.

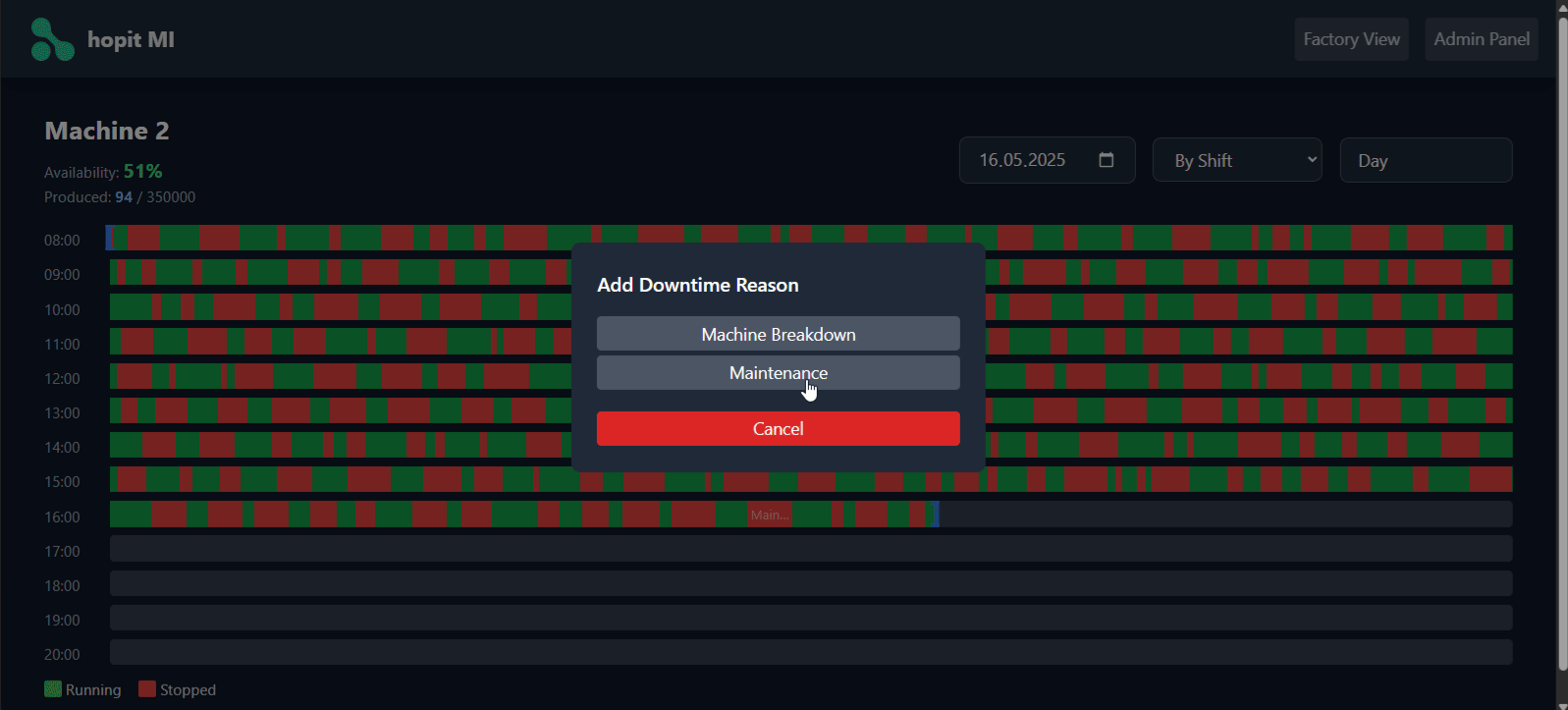

Downtime Tracking

With digital downtime tracking, you immediately detect production interruptions, analyze causes and reduce unplanned downtimes. This increases equipment availability and sustainably reduces costs.

Real-time KPIs

Key figures for quality, performance and availability at a glance.

Energy Monitoring

Measurement of required power to reduce energy consumption.

Alarms & Notifications

Alarms and notifications in real time for faulty machine states.

Frequently Asked Questions

Ready for more efficient production?

Get started within 2 weeks.